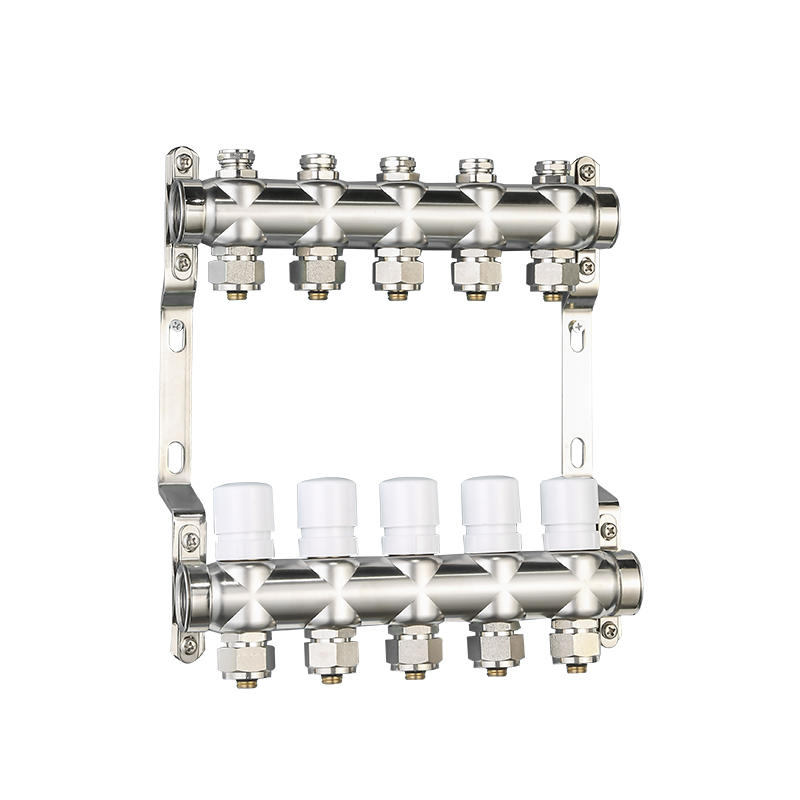

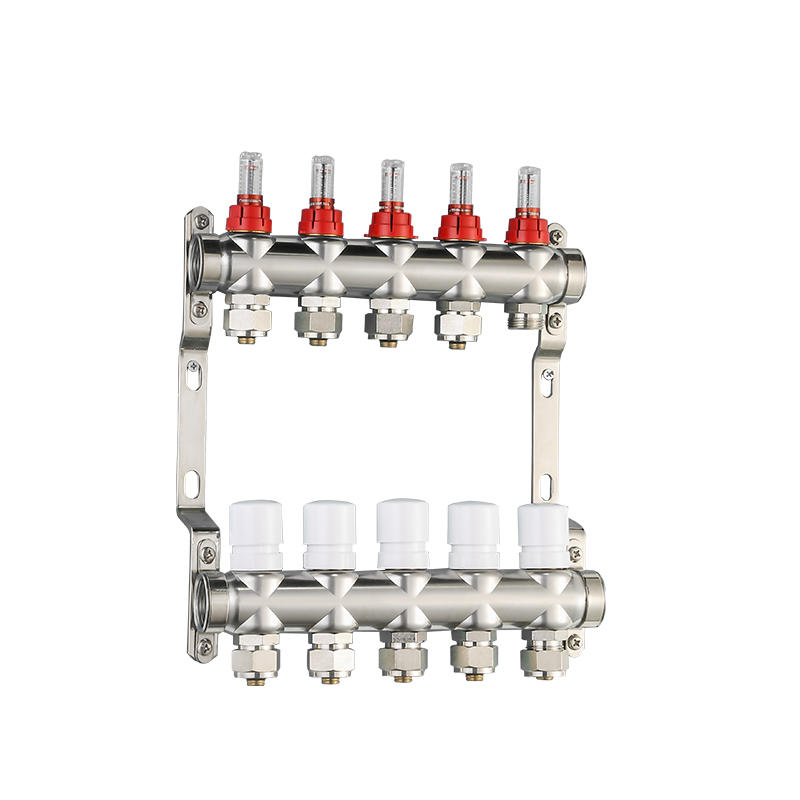

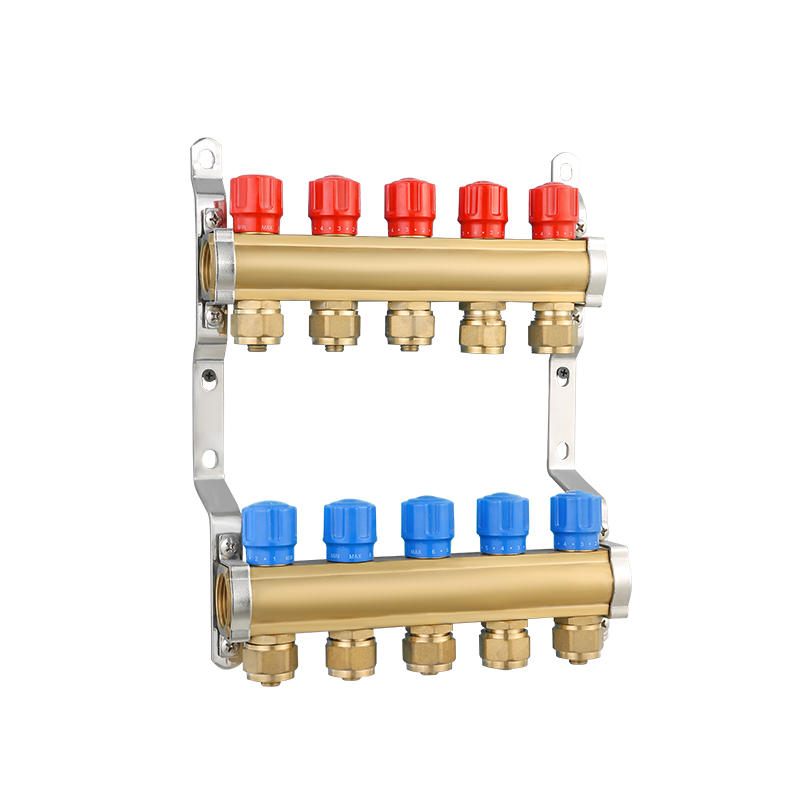

Wholesale High Quality Flow Matrix Manifold Supplier

Hydraulic systems are the backbone of many industrial processes, providing the power and precision necessary for a wide range of applications. At the heart of these systems lies a critical component: the manifold. A manifold is an integrated assembly that connects various hydraulic components, such as pumps, valves, and actuators, to streamline the flow of fluid power. The role of a manifold supplier is not just to provide these components but to ensure that they are tailored to the specific needs of the system, thereby enhancing its efficiency and performance. In this article, we will explore the multifaceted role of a Wholesale Flow Manifold in optimizing hydraulic systems.

A good manifold supplier begins by understanding the intricacies of the hydraulic system in which their manifolds will be integrated. This involves a thorough analysis of the system's requirements, including pressure, flow rate, and temperature specifications. By doing so, the supplier can ensure that the manifolds they provide are designed to meet these specific needs, resulting in a more efficient and reliable system.

One of the key roles of a manifold supplier is to offer customization options. Standard manifolds may not always fit the unique requirements of every hydraulic system. A supplier that can customize manifolds to fit the exact dimensions, port configurations, and material specifications of a client's system is invaluable. This level of customization ensures that the manifolds integrate seamlessly with the rest of the hydraulic components, reducing potential inefficiencies.

The choice of materials is another critical aspect where a High Quality Matrix Manifold can impact the efficiency of hydraulic systems. Different materials have varying levels of resistance to wear, corrosion, and heat. A knowledgeable supplier will select materials that not only meet the performance requirements but also offer longevity, reducing the need for frequent replacements and reducing downtime.

The role of a manifold supplier extends to ensuring that the manifolds are compatible with other components in the hydraulic system. This includes compatibility with various valve types, actuators, and other hydraulic accessories. A supplier that offers a range of compatible products simplifies the process for system designers and operators, resulting in a more efficient and cohesive system.

Beyond the physical supply of manifolds, a top-tier manifold supplier provides technical support and consultation services. This can include assistance with system design, troubleshooting, and performance optimization. Expert advice from a supplier can help clients overcome technical challenges and enhance the efficiency of their hydraulic systems.

The relationship with a manifold supplier does not end with the initial purchase. A reliable supplier offers ongoing support and service, including maintenance, repairs, and upgrades. This ensures that the hydraulic system continues to operate at efficiency over its lifetime.

A forward-thinking manifold supplier stays abreast of industry trends and technological advancements. By incorporating new materials, designs, and manufacturing techniques, a supplier can offer manifolds that are at the cutting edge of efficiency and performance. This not only benefits the client's current system but also prepares them for future upgrades and improvements.

In today's environmentally conscious climate, a manifold supplier that prioritizes sustainability can make a significant difference. This can include using recycled materials, reducing waste in the manufacturing process, and designing manifolds that reduce energy consumption. By doing so, a supplier can help clients reduce their environmental impact while still achieving high levels of system efficiency.

The role of a manifold supplier in enhancing the efficiency of hydraulic systems is multifaceted and critical. From the initial design and customization to ongoing support and innovation, a supplier's expertise and services can significantly impact the performance, reliability, and longevity of hydraulic systems. By choosing a manifold supplier that excels in these areas, clients can ensure that their hydraulic systems operate at their efficiency, providing a solid foundation for their industrial processes.

English

English Español

Español русский

русский Deutsch

Deutsch