Custom OEM Distribution Zone Valve Manifold Supplier

In the intricate world of manufacturing, efficiency, precision, and reliability are paramount. Modern manifold suppliers play a crucial role in ensuring these qualities are met, providing essential components that facilitate the smooth operation of various industrial processes. From hydraulic systems and pneumatic machinery to fluid distribution networks and beyond, manifold suppliers serve as indispensable partners in the manufacturing ecosystem. In this comprehensive exploration, we delve into the multifaceted role of Custom Distribution Manifolds in modern manufacturing, examining their contributions to productivity, innovation, quality, and sustainability.

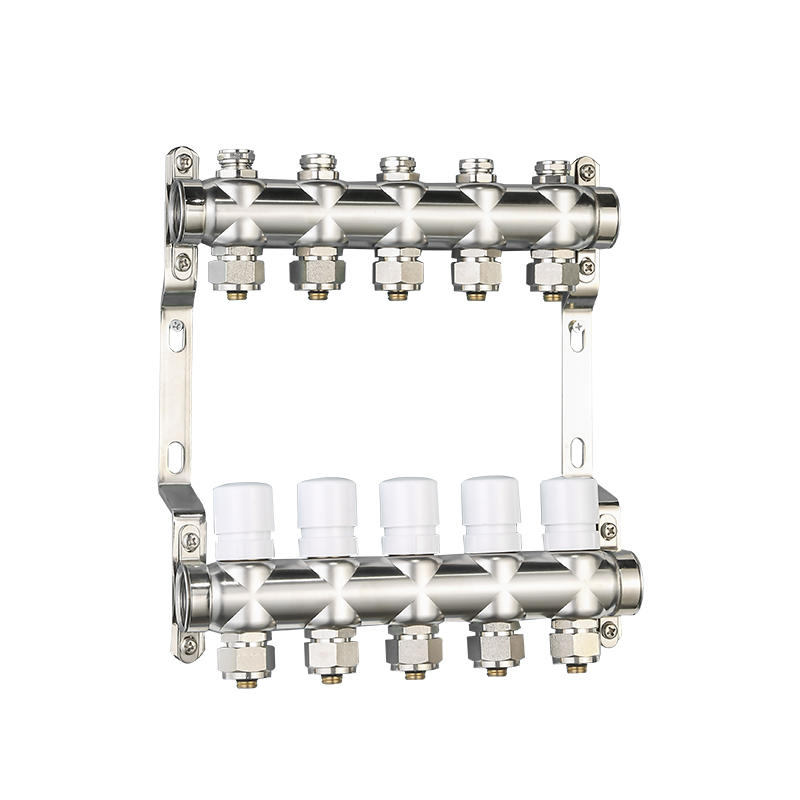

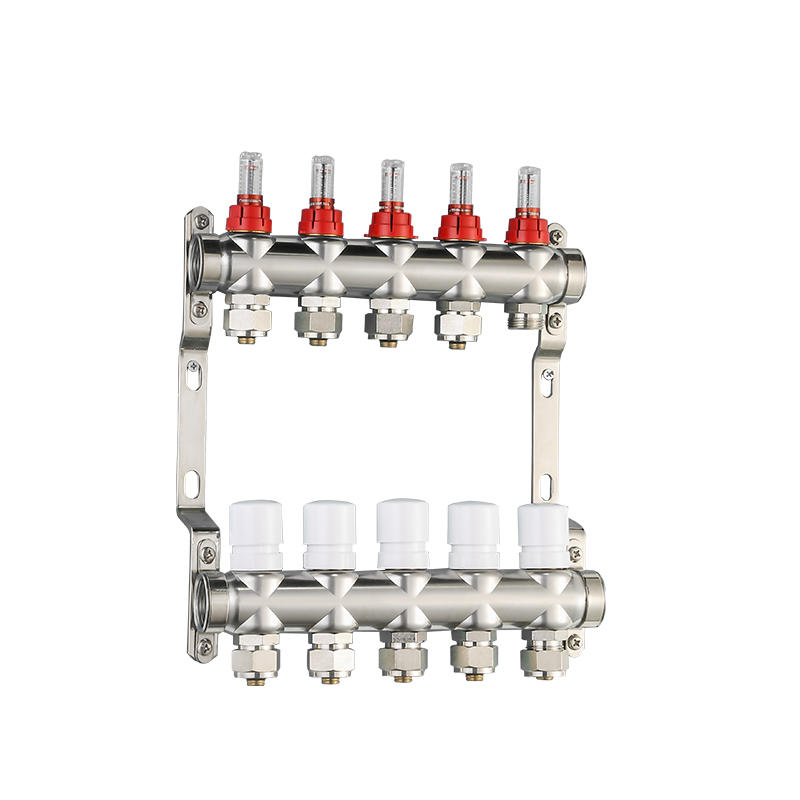

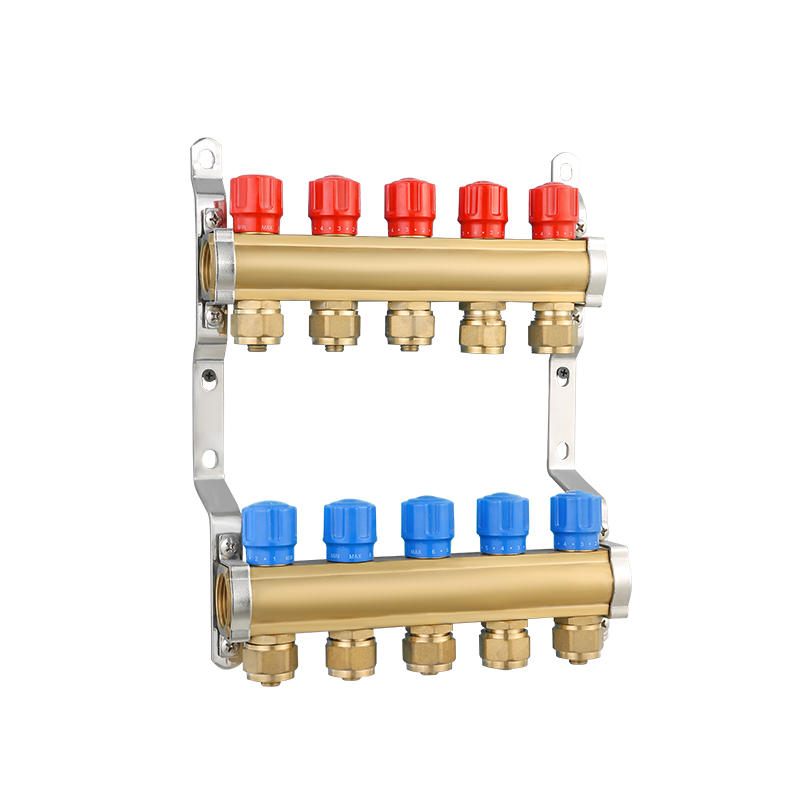

Manifolds serve as central hubs for fluid control systems, facilitating the distribution, regulation, and direction of liquids or gases within industrial machinery and equipment. Modern manifold suppliers specialize in designing and manufacturing these critical components, offering a diverse range of configurations, materials, and features to meet the specific needs of different applications. Whether it's a hydraulic manifold for heavy machinery or a pneumatic manifold for automated assembly lines, suppliers provide essential solutions that enable efficient fluid management and control.

One of the key strengths of modern manifold suppliers lies in their ability to offer customization and tailored solutions to meet the unique requirements of their customers. Manufacturers often have diverse product lines and engineering capabilities to design and produce custom manifolds according to specific dimensions, flow rates, pressure ratings, and compatibility with different fluids or gases. By working closely with customers to understand their needs and challenges, manifold suppliers deliver solutions that optimize performance, reliability, and cost-effectiveness for various manufacturing applications.

As manufacturing processes become increasingly automated and sophisticated, manifold suppliers are at the front of integrating advanced technologies into their products. This includes incorporating sensors, actuators, electronic controls, and IoT connectivity into manifold designs to enhance functionality, monitoring, and diagnostic capabilities. Smart manifolds equipped with these technologies can provide real-time data on fluid flow, pressure, temperature, and other parameters, enabling predictive maintenance, remote monitoring, and optimization of manufacturing processes.

By providing efficient and reliable fluid control solutions, manifold suppliers contribute to productivity enhancements in manufacturing operations. Well-designed manifolds streamline fluid distribution, reduce pressure drops, and reduce energy consumption, resulting in optimized performance and throughput. Moreover, modern manifold designs incorporate features such as quick-connect fittings, modular construction, and easy-to-service components, simplifying installation, maintenance, and troubleshooting for users.

Manifold suppliers continually push the boundaries of material science and manufacturing processes to enhance the performance, durability, and sustainability of their products. Advanced materials such as stainless steel, aluminum alloys, and engineered plastics offer strength, corrosion resistance, and weight savings compared to traditional materials. Furthermore, innovative manufacturing techniques such as CNC machining, additive manufacturing (3D printing), and laser welding enable the production of complex manifold designs with tight tolerances and intricate features.

In conclusion, modern manifold suppliers play a multifaceted role in manufacturing, providing essential components, customized solutions, and technological innovations that drive efficiency, productivity, and sustainability. From hydraulic and pneumatic systems to fluid distribution networks and beyond, manifold suppliers are integral partners in the success of manufacturing operations across diverse industries. By embracing advanced technologies, prioritizing quality assurance, supporting sustainable practices, and fostering collaboration, manifold suppliers empower manufacturers to achieve their goals and remain competitive in today's dynamic marketplace. As manufacturing continues to evolve, OEM Zone Valve Manifolds will continue to play a pivotal role in shaping the future of the industry and driving innovation forward.

English

English Español

Español русский

русский Deutsch

Deutsch