OEM Custom Traditional Corner Polished Brass Radiator Valves Manufacturer In the world of home comfort, the radiator valve is a small but mighty hero. It's the unsung savior that ensures your home is ...

Product Category:

Product:

We can save cost and create value for you

Our Products

-

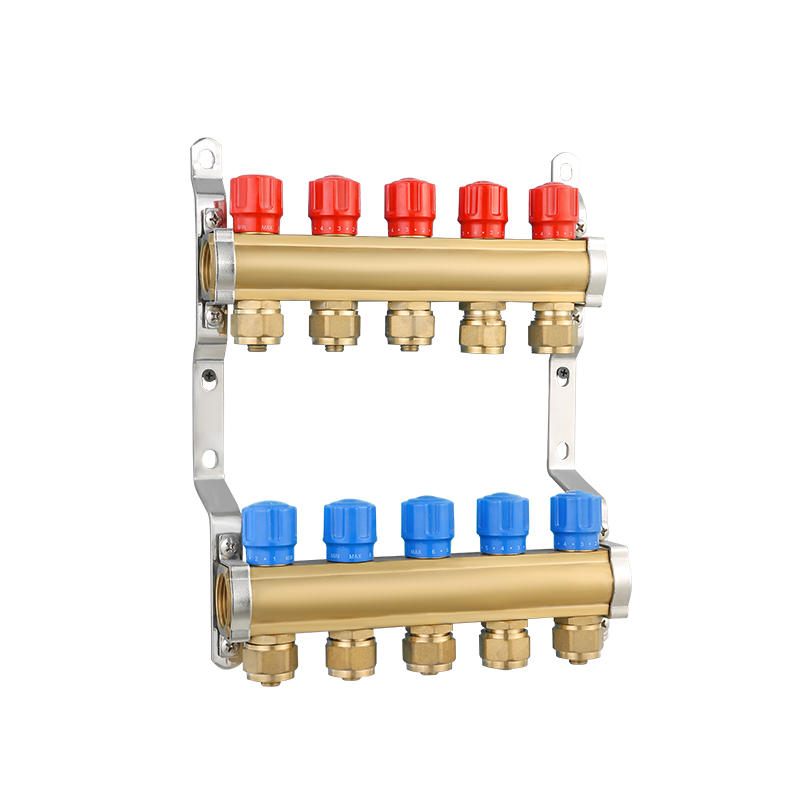

Brass Radiant Heat Manifold for Floor Heating

-

Underfloor Heating System Brass Manifold Valve

-

Automatic temperature control Brass Manifold

-

Floor Heating Radiant Brass Manifold With Flow Meter

-

Nickel Plated Brass Manifold for Floor Heating System

Brass Manifold Manufacturers

Made of brass material, durable and pressure resistant. The manifold plays the role of shunt, and the heat source and hot water are separately imported into the pipe laid by the ground radiation heating house in each way, so as to achieve the purpose of sub-room heating and temperature regulation. The pipeline direction of the manifold is clear,it is easy to operate, easy to disassemble and maintain, and can reduce the system pressure difference.

25 years of experience

Zhejiang Huibo Valve Technology Co., Ltd.

Zhejiang Huibo Valve Technology Co., Ltd. is a leading Wholesale Brass Manifold Manufacturers and Brass Manifold Factory in the valve industry, with more than 25 years of experience, specializing in the field of HAVC system parts and brass valves. Huibo Valve has its own factory, which is located in Yuhuan County, Zhejiang Province, the hometown of brass valves in China.Now as the top manufacturer of high quality HAVC system parts and brass valve, our main products cover brass manifold, stainless steel manifold, thermostatic radiator valve, manual radiator valve,balance valve, motorized valve, air vent, ball valve, gate valve, gas valve, check valve, brass fittings and so on with more than 40 series and 2000 varieties.

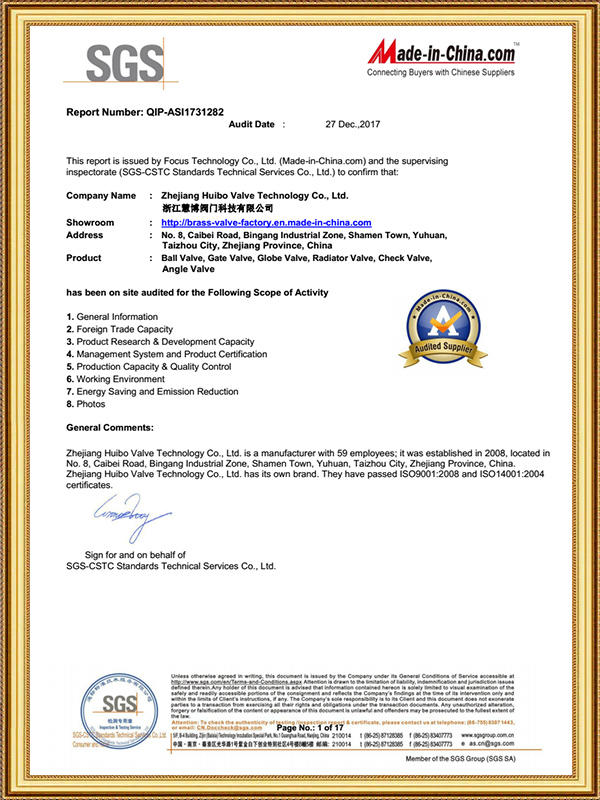

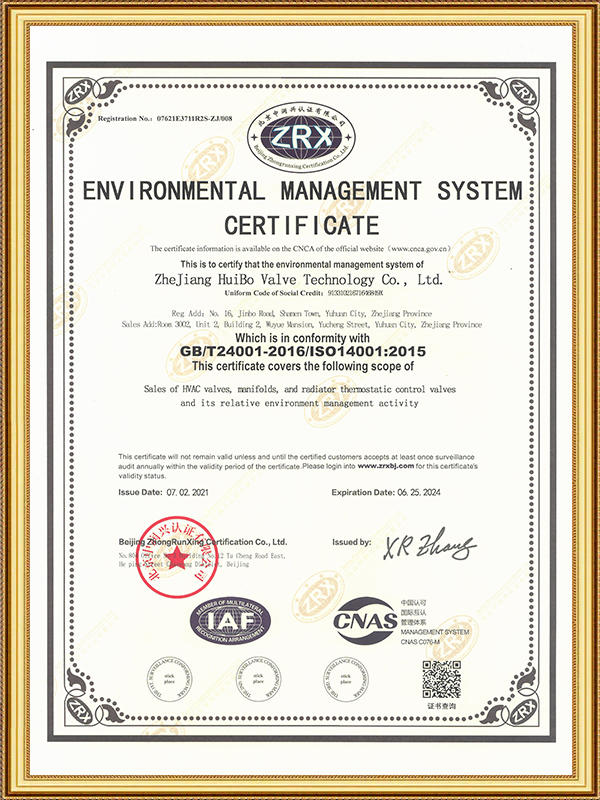

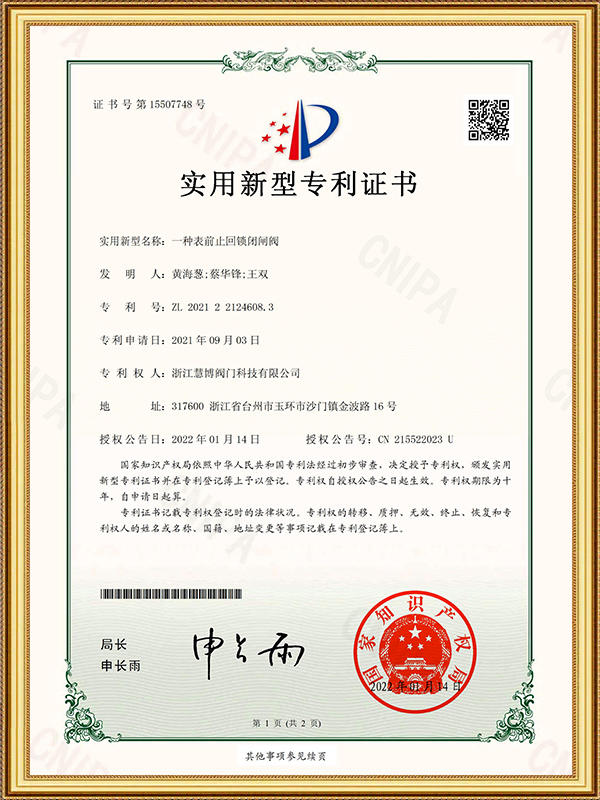

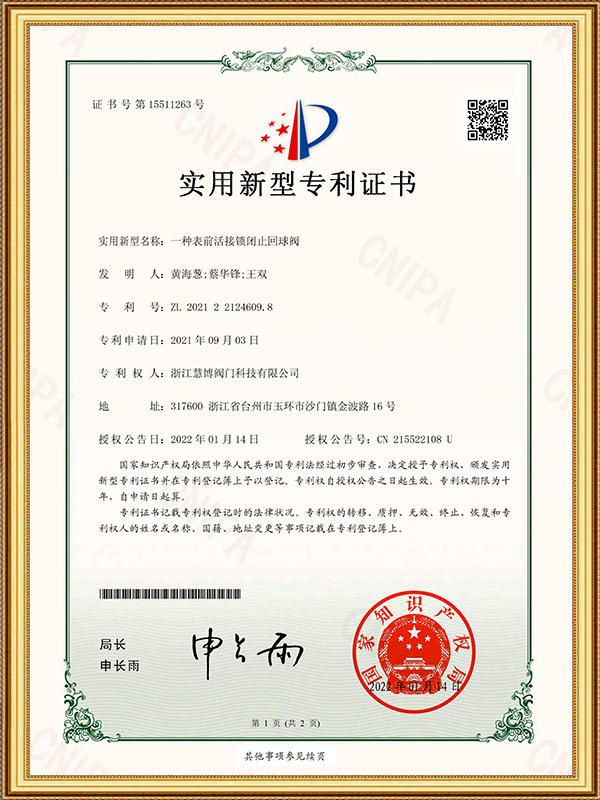

CERTIFICATE

OUR LATEST NEWS

-

How Radiator Valve Manufacturers Tailor to Your Needs?

Read More + -

The Role of Radiator Valve Manufacturers in Modern Homes

Read More +Wholesale Custom Traditional Chrome Nickel Radiator Valves Manufacturer In the quest for energy efficiency and comfort, the role of radiator valve manufacturers has become increasingly significant in ...

-

Why is a radiator valve manufacturer important in the art of heating?

Read More +Sale OEM Square Angled Traditional Straight Radiator Valves Manufacture The art of heating is a delicate balance of aesthetics, efficiency, and comfort. It's not just about warming a space, but doing ...

-

A Guide to Choosing the Right Radiator Valve Manufacturer

Read More +China Cheap Radiator Brass Angled Radiator Chrome Corner Valves Manufacturer When it comes to home comfort and energy efficiency, the role of radiator valves cannot be overstated. These small but cruc...

Industry Knowledge Extension

The working principle of Brass Manifold

How to Use Brass Manifold?

English

English Español

Español русский

русский Deutsch

Deutsch