Selecting the appropriate Air Vent Valve is an important step in ensuring efficient operation in various plumbing, heating, and ventilation systems. The role of a Valve is to release trapped air from pipelines or tanks, which helps maintain system performance and prevent issues caused by air pockets. Understanding the key factors when choosing a Valve can help users achieve better system efficiency and reliability.

One of the considerations in selecting an Air Vent Valve is the type of system it will be used in. Different systems have varying requirements depending on factors like operating pressure, temperature, and the fluid being handled. For example, heating systems might need a Valve designed to withstand high temperatures, while water supply systems may require valves compatible with potable water standards.

The size of the Valve is another crucial aspect. The valve should match the diameter of the pipe or vessel it serves to ensure proper air release without causing leaks or pressure drops. Many manufacturers offer a range of sizes, so it is helpful to measure the existing system components and consult specifications when choosing a Valve.

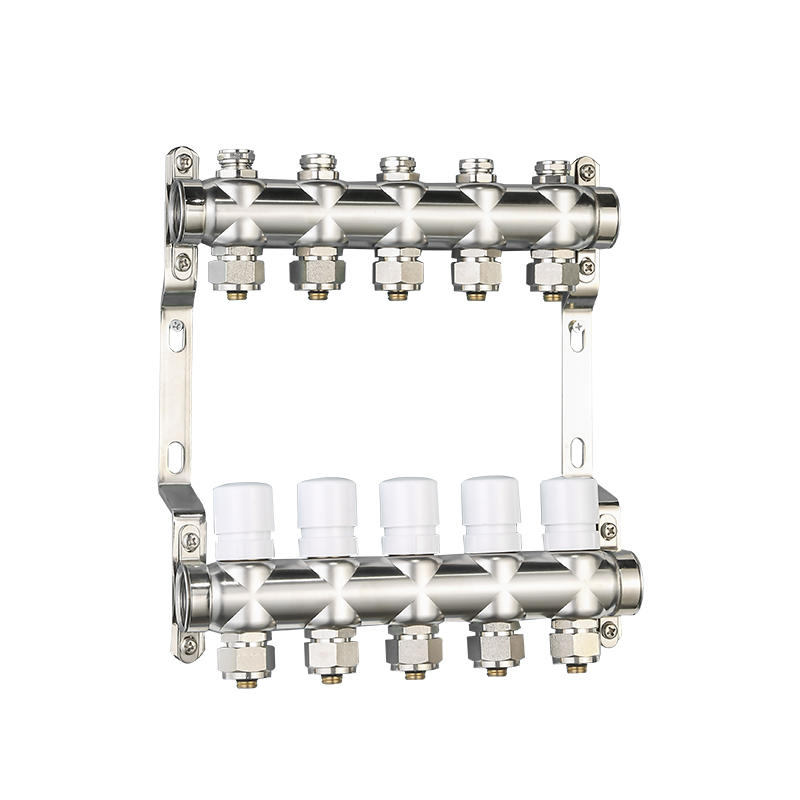

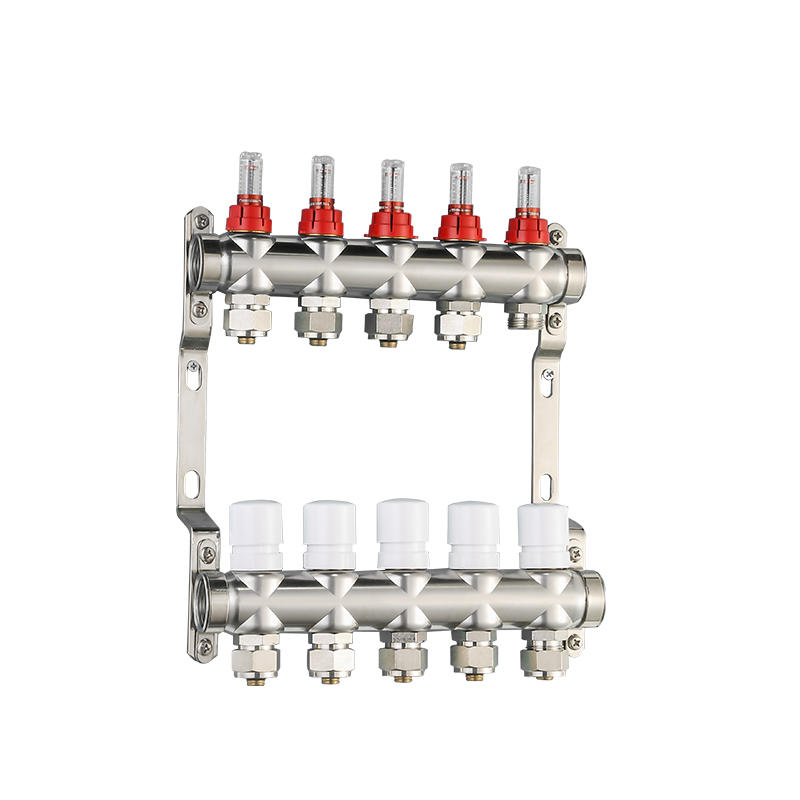

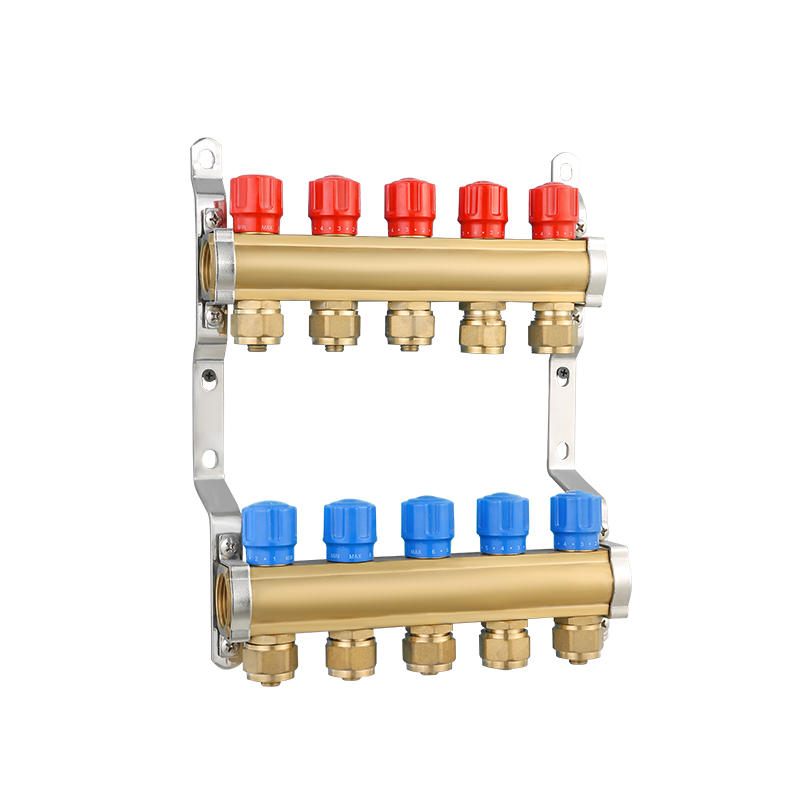

Material choice plays a significant role in the longevity and suitability of an Air Vent Valve. Common materials include brass, stainless steel, and plastic composites. Each material offers different resistance levels to corrosion, temperature, and wear. For example, stainless steel valves tend to offer better resistance in harsher environments, while brass valves are widely used in residential heating systems.

The mechanism of the Air Vent Valve is another feature to consider. Some valves use float-operated designs, where a float inside the valve opens and closes the air outlet as air accumulates or is released. Other types include fixed orifice valves that allow a steady release of air. Choosing the right mechanism depends on the system’s air release needs and maintenance preferences.

Installation ease and maintenance requirements can influence the choice of an Air Vent Valve. Valves that are easy to access and clean can save time and effort over the system’s lifetime. Some models offer removable parts or simple designs that facilitate routine inspections and repairs.

Another factor is the valve’s pressure rating. The Valve should be capable of operating under the system’s pressure without failure. Checking the manufacturer’s specifications for pressure limits helps avoid selecting a valve that might be unsuitable for high-pressure applications.

Compatibility with system fluids is also important. If the system handles chemicals or aggressive fluids, it’s essential to choose an Air Vent Valve made of materials resistant to those substances. This consideration helps prevent premature valve failure and contamination of the fluid.

Noise levels during operation may be a concern in residential or commercial environments. Some Air Vent Valve designs reduce noise while releasing air, improving comfort without compromising functionality. Evaluating noise factors can be useful for installations in quiet spaces.

Some Air Vent Valve models include features like integrated filters or strainers to prevent debris from clogging the valve. These additional features can enhance valve reliability and reduce maintenance frequency, benefiting overall system performance.

It is also helpful to consider the valve’s sealing capability. A good seal prevents water or fluid leakage while allowing air to escape when necessary. Poor sealing can cause system inefficiency or damage, making valve selection critical.

The lifespan of the Air Vent Valve depends on its design, material, and operating conditions. Choosing a valve from manufacturers with clear quality control measures can provide assurance that the valve will perform as expected over time.

Finally, considering warranty and customer support can be beneficial. Some suppliers offer extended support or replacement options for their Air Vent Valve products, which may add value during installation and use.

English

English Español

Español русский

русский Deutsch

Deutsch